Punching processes at a glance: Rotary die-cutting vs. flatbed die-cutting

Die-cutting is a separation process that is used, among other things, in the production of labels or corrugated cardboard packaging. A distinction is made between rotary die-cutting and flatbed die-cutting. Both variants offer advantages and disadvantages and are partly suitable for different fields of application.

Definition: What does punching mean?

The term "punching" stands for processes in which material parts are separated from the surrounding material under pressure. In label production it is used to remove individual labelsfrom rolls of raw material, in the cardboard and corrugated board industry to produce cardboard blanks or custome-made cartons from rolls or sheets and to pre-score folds. This may sound simple at first. However, die-cutting is a very complex process, the result of which can be influenced by various factors.

For example, it depends on whether you want to punch completely through the source material or only punch it. The former means that the material is completely cut through. As a result, you get separate flat parts (e.g. labels or cardboard cut-outs). In contrast, die-cutting leaves at least one layer of the raw material intact. An example of this is label sheets, where the backing material forms a unit while the labels on it are already cut out and easy to peel off. Which die-cutting process is best suited for what ultimately depends on the desired result.

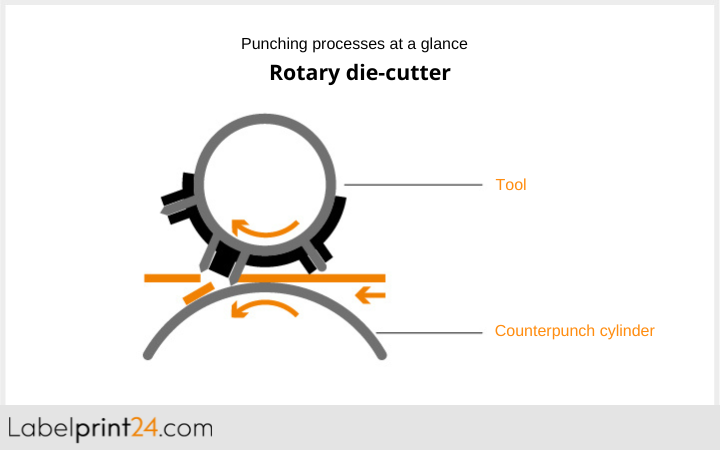

Structure of the rotary die cutter

In the rotary die cutter, the punching tool is located on a rotating magnetic cylinder. The counterpart is the counter-pressure cylinder, which guides the raw material to be punched past the magnetic cylinder at a suitable speed, thereby generating the pressure required for the punching process.

The die-cutting tools for rotary label die-cutting are usually thin, bendable metal plates on whose surface the desired die-cutting shape appears as an elevation. The respective plate is wrapped around the magnetic cylinder and held there by magnetic forces. There are also fixed die-cutting cylinders, but these are rarely used due to their high manufacturing costs and are not suitable for every die-cutting machine.

Plywood cutting dies are mainly used for cutting corrugated board. The cutting contours are cut with the help of a thin saw or a laser beam and then equipped with the required cutting or creasing lines. These are brought into the required shape in advance using a cold bending process.

Functionality and advantages of the rotary die cutter?

The roll-shaped raw material is clamped onto the machine and threaded so that the impression cylinder can pull it past the magnetic cylinder. The cutting edges of the cylinder punch the material to the desired depth. The finished punched parts are then separated from the waste.

When die-cutting labels, the waste grid consisting of the remnants of all layers is rolled up, while the die-cut segments are collected elsewhere. If the raw material is only die-cut, both the backing material with the labels on it and the waste grid consisting only of the top material remnants are rolled up. The latter simplifies disposal. The advantages of rotary die-cutting are:

- the high production speed,

- the higher degree of precision compared to flatbed machines,

- the ability to perform several functions simultaneously (e.g. perforating, printing, laminating),

- the option of kiss-cutting, which involves cutting only the main material while leaving the backing paper intact.

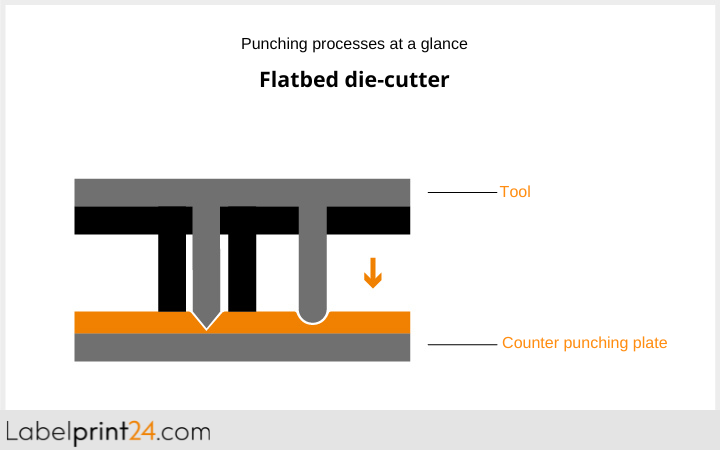

Design, mode of operation and advantages of flatbed die-cutters

Flatbed die-cutters do not use the rotary process. Instead, they press a flat punching tool onto the material from above. The machines, also known as lifting die cutters, offer the advantage that cutting plates in common formats are available at low cost. In addition, the tool is easier to change, which makes the process particularly suitable for frequently changing batches.

In the label sector, this die-cutting technique is used less frequently than rotary die-cutting. When cutting corrugated board, the production sequence begins with the feeding of the sheets via a sheet feeder. The feeder moves the raw material under a tool that has the desired contours (cuts and creases).

- the possibility of cutting thicker and denser materials, as the machines can be opened wide,

- the greater variety of materials to be processed (thick, thin, sheets, rolls),

- the lower cost, and

- the possibility of grouping parts closer together (less waste).

The right die cutter for every application

When deciding between rotary and flatbed die cutters, you should ask yourself the following questions in particular:

- How thick is your material?

- Is your material in rolls or sheets?

- What are your speed and volume requirements?

Both punching variants can cope with thin materials. For thicker and denser materials, however, flatbed die-cutting is more suitable. Although this is inferior to the rotary process in terms of precision, it enables sufficiently clean and precise cuts for most fields of application. For rotary die-cutting, the raw material must run on a ro If you want to process materials in sheet form, for example corrugated sheets, the flatbed die cutter is the right choice. For high order volumes, the rotary die cutter is recommended, which allows significantly faster throughput times and thus much higher production rates. The same applies if you want to perforate, print and laminate in one operation. Rotary die-cutting is more expensive than flatbed die-cutting because the processing of the cutting dies incurs higher costs. ll so that the machine can feed it in.

If you want to process materials in sheet form, for example corrugated sheets, the flatbed die cutter is the right choice. For high order volumes, the rotary die cutter is recommended, which allows significantly faster throughput times and thus much higher production rates. The same applies if you want to perforate, print and laminate in one operation. Rotary die-cutting is more expensive than flatbed die-cutting because the processing of the cutting dies incurs higher costs.

What needs to be considered during the die-cutting process?

Whether flatbed die-cutter or rotary die-cutter: You can only achieve optimum results if you align the die-cutting process exactly to the respective starting material. The thickness of the material plays just as important a role as the nature of the raw material. Tough materials, for example, are punched at a steep angle so that they cannot stretch before they come loose. This is not necessary with paper labels or corrugated board, as these materials can be cut through very easily. However, the die-cutting tool is subject to greater wear than when die-cutting smooth film materials and therefore needs to be cleaned and sharpened more frequently.

Another important factor is the cutting gap, which defines the distance between the cutting tool and the counter-pressure cylinder. If it's too small, there's a risk of punching through the entire starting material even if only partial cutting was intended. Conversely, if it's too large, the punch doesn't cut deep enough. In label die-cutting, this would mean that the upper material and adhesive don't separate cleanly. In corrugated cardboard, creases wouldn't be sufficiently scored, which would complicate folding.